MCS Goup’s PRC Tech Streamlines Subsea Ops for Shell JV off Egypt

MCS Group’s Photo Realistic 3D Cloud (PRC) technology has been deployed in the West Delta Deep Marine (WDDM) gas field development offshore Egypt, improving accuracy and reducing subsea survey time for Burullus Gas Company, a joint venture between Shell and the Egyptian General Petroleum Corporation (EGPC).

The WDDM’s Phase 10 and Phase 11 engineering, procurement, installation, and commissioning (EPIC) projects were executed by Egypt-based firms MCS Group and Petroleum Marine Services (PMS). The program integrated six new subsea wells into existing offshore infrastructure, with PRC technology providing precise subsea measurements.

Scope and Operations

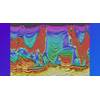

UTA - PRC 3D point cloud during the umbilical laying (Credit: MCS Group)

The project scope included jumper metrology to enable the accurate installation of eight subsea jumpers linking six wells, umbilical installation surveys, and pre-engineering and as-built surveys to generate detailed 3D models of the subsea environment.Key technical tasks involved the installation of eight 29-metre jumpers with millimeter accuracy, precise laying of two umbilicals, 5 km and 2 km in length, and providing 3D visualization to detect and correct misalignments.

Also, the scope of the job covered verification surveys to ensure alignment and structural integrity.

Four-Stage Process

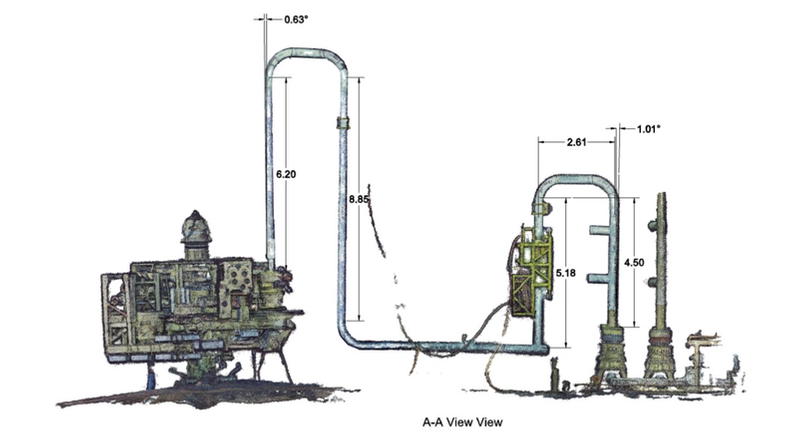

TSB - PRC 3D Point Cloud during the Pre-Engineering Survey (Credit: MCS Group)

TSB - PRC 3D Point Cloud during the Pre-Engineering Survey (Credit: MCS Group)

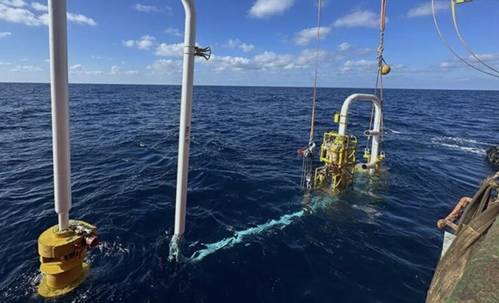

The operation was carried out in four stages. During umbilical laying in Phase 10, an ROV from DeepTech, a MCS Group’s company, equipped with PRC cameras positioned mudmats relative to subsea structures, ensuring correct alignment and avoiding interference with existing assets.

Using PRC system, the pre-engineering surveys generated 3D point cloud models of subsea structures such as PLETs, UTAs, X-Trees and HIPPS, delivering precise measurements for jumper fabrication. Using the PRC software, the data was then processed into 3D models that formed the basis for jumper design. Validated designs enabled seamless installation, executed with DeepTech’s ROVs, according to MCS Group.

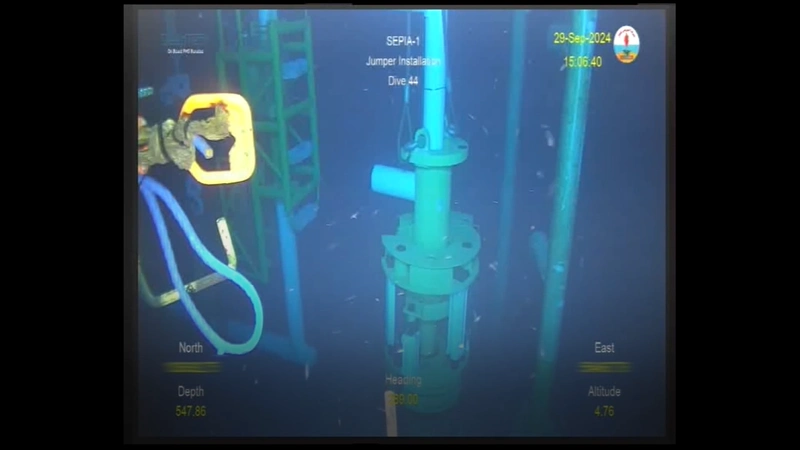

As-Built Survey Conducted by DeepTech Work-class ROV and MCS PRC Cameras (Credit: MCS Group)

Following fabrication and installation, the post-installation surveys confirmed the positioning and integrity of the jumpers. PRC system data supported stress analysis and demonstrated compliance with project standards, ensuring long-term reliability.Outcomes

As-Built PRC 3D Point Cloud model: Measurements After Jumper Installation (Credit: MCS Group)

According to MCS Group, the application of PRC technology produced measurable benefits across Phases 10 and 11. Surveys were completed in three to five hours per structure, compared with longer durations under traditional long baseline (LBL) methods. The system achieved 0.001-meter linear accuracy, allowing precise fabrication and alignment.Detailed 3D models provided comprehensive insights, enabling visualizations of subsea assets, identification of misalignments, and flexibility to accommodate additional requirements.

The project marked a significant improvement in subsea metrology and installation efficiency for Burullus Gas Company and its partners, with MCS Group’s PRC technology playing a central role in enhancing accuracy, reducing downtime, and optimizing offshore operations, the Egyptian contractor said.

February 2026

February 2026