Tidal turbine ballast might be the answer in the search for reliable and economical solutions

Alternative and in particular marine renewable energy sources have recently become very popular due to all natural disasters caused by the severe climate changes and the high levels of carbon dioxide in the atmosphere. Wind and sun possess high energy potential, but their outcome remains quite unpredictable, consequently unreliable and expensive. Opposed to that ocean power is based on natural regularities as ebb and flow tides and can be planned and controlled. This is also the reason why many big and even not so big economies started investing in small and huge projects, sponsoring the design, manufacture and installation of tidal turbine configurations. Therefore tidal turbines have become the most critical element in the future development of the marine renewable energy sector.

The Tidal Turbine and Its Installation Challenges

Most tidal turbines feature the same main components: blades, generator, hub and foundation. Structural differences depend on the level of performance that need to be achieved and the seabed surface.

The part that is constantly evolving and keeps the minds of designers and manufacturers busy is the

tidal turbine foundation. The way the device should be attached is of critical importance since strong currents can be extremely aggressive environment. Current solutions as drilled piles or monopiles are quite expensive because they require seabed geology and bathymetry analysis, complicated design, additional machinery for installation and frequent maintenance due to corrosion, fatigue cracks and the grout.

Gravity-based foundations can be eventually considered as the better solution since they don’t penetrate the seabed. However, the overturning moments need to be carefully considered and if the ballast is made of concrete, the footprint can irreversibly damage the seabed. Furthermore, concrete made gravity-based foundations require a massive supporting structure leading to high material and logistic costs.

Rarely used are suction bucket anchors and moored floating structures, preferable for deeper water. There are also several hybrid projects as the gravity-pile and jacket-monopile hybrids and tripod structures.

And even though all the mentioned foundations are obviously very different in terms of configuration and consisting components, they all feature the following common drawbacks:

- Expensive in-depth geological analysis

- Complicated configuration that requires short interval maintenance

- Inconvenient and laborious installation

- Penetration of the seabed with possible damages of the surface

Considering all this the marine renewable sector is in a constant search of better materials to design and manufacture better tidal turbine’s foundations.

Gray Cast Iron Ballast Might Be the Answer

Gray cast iron tidal turbine ballast guarantees the stability of the foundation and thus it is of critical importance for the performance of the entire configuration. It is made of recycled steel and it doesn’t damage the environment because of the positive carbon assessment. Furthermore cast iron is four to five times denser than concrete, which makes it achieve the target weight in less space and volume compared to concrete, enabling an easy installation.

Gray cast iron tidal turbine ballast usually comes in three possible designs to easily adapt to the specific technology of the gravity base: as a welded cylindrical base reinforced by ballast; as a welded base with a central stake, manufactured without formwork and that can be integrated onshore or offshore; as a reinforced concrete base.

The solution represents a new technology to fix the device to the seabed that doesn’t require in-depth geological analysis and frequent maintenance because of its simple but robust design. It doesn’t pierce the sea floor and once removed it doesn’t impact the surface.

The tidal turbine ballast made of gray cast iron marks an important milestone in the development of marine technologies.

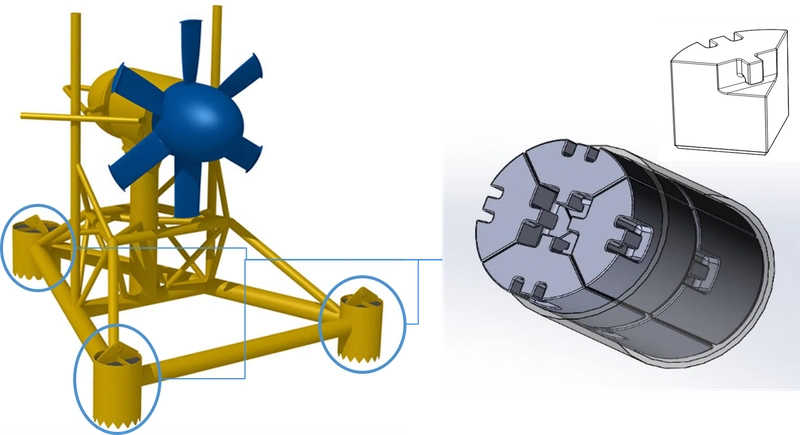

The Case Study: Sabella

The French company Sabella has developed a new tidal turbine with an innovative gravity-based foundation, fixed to the seabed only with cast iron ballast; without penetration. The manufacturer of the ballast is FMGC – the European leader in cast iron counterweights. The new solution was tested and applied on the turbine in the waters of the Fromveur passage, near Ushant in Brittany. FMGC incorporated in the welded gravity base with cylindrical legs 10 metric tons of cast iron ballast in the nacelle and 180 metric tons in total in the supporting legs. The use of cast iron enables to reduce by three the volume and the weight of the turbine support structure. Compared to drilled monopile foundations, the gravity tripod base is less expensive and requires far less time and efforts for installation. After the ballast has been attached to the device onshore, a crane places the turbine on the required place. The configuration doesn’t accommodate human operators and can be “dropped” in hostile locations with the heavy-duty machine.

The tripod structure eliminates the impact of a standard concrete gravity foundation and facilitates a better lateral stability, stiffness and eco-friendly installation.

The raw material selection of the ballast and the finishing coating results in best possible mechanical properties of the component, which minimizes the risk of failure and therefore maintenance. It is proven that gray cast iron delivers the strongest resistance against any possible impact and there are simply no components that could require additional maintenance due to erosion or any other coating damage.

During the design phase, any eventual additional problem as (wave loadings, wave pressure or wave affected zone) has been calculated.

Benefits of Gray Cast Iron

The main benefits of gray cast iron for the MRE sector can be summarized as follow:

- Best structural reliability

- Minimized impact of the foundation on the seabed

- Reduced surfaces exposed to hydrodynamic forces

- Optimized transport and logistics costs

- Simplified handling

- Easy installation

- High density

Tidal turbine ballast made of gray cast iron is an innovative solution that will enormously contribute to better marine technologies in the next years. Harnessing tidal energy in a best way in order to deliver clean energy future is the main concern of all industrial keyplayers. The entire sector is continuously evolving, in a constant search of better products.

The Author

Ralitsa Peycheva is a technical content manager at Farinia Group, interested in forging and casting techniques, latest machinery and tools; curious about new manufacturing methods; respecting high-quality engineering.

December 2025

December 2025