MacArtney, Teledyne ODI Expand Connector Service Across Europe

. As part of MacArtney’s European offering, this location brings inspection, fault diagnosis, and repair capabilities closer to operators across the region, enabling more responsive support for those working with Teledyne ODI products.MacArtney’s servicing covers individual Teledyne ODI connectors, complete cable assemblies, and integrated systems. By addressing performance at both the component and operational levels, such as underwater frames and sensor packages, MacArtney helps operators maintain equipment integrity and avoid costly replacements.In addition to standard repairs, MacArtney

Lander Lab: Selection Criteria for Underwater Cable and Connectors

Underwater connectors and mating cables provide system flexibility, ease of service, and other advantages to undersea system designers and field engineers.They also bring their own suite of added complications and problems.There is a lot to consider. System designers need to be conscious of the connector they select. A criteria-of-selection provides a programmatic approach to narrowing down and choosing the right underwater connector. Sales reps can provide guidance, but it is ultimately the responsibility of the engineers to write the specifications.I’ve always held that connectors are a

Upscaling Power Subsea: Cables and Connectors

Cable and connector manufacturers are rushing to meet the growing demand for subsea cables and connectors as renewables upscale, but whether it’s renewables or oil and gas, there’s also growing demand for high-tech subsea communications.The export cables that bring offshore wind power to shore are already so massive that one meter of cable can weigh 300kg. Nexans had previously upscaled its production facilities to cater for increasing demand; now it is upscaling its HVDC cables, typically 400kV, to 525kV. The company will be supplying at least 10 of these cable systems to European grid

MacArtney Introduces 9-Contact SubConn Connector

, such as AUVs, ROVs, sensors and multiplexers.The 9-contact connector's design and versatility facilitate integration into the increasingly compact design of underwater technology solutions while still meeting complex data and power transmission needs with its multi-signal capabilities. 8-contact connectors are typically used for signal transmission, and some users have requested an additional contact for enhanced security. The ninth contact in this connector is intended for a screen, providing an extra layer of data protection and ensuring reliable performance.The SubConn Micro Circular connector

Connectors Facilitate Camera System for BBC Underwater TV Series

Teledyne Impulse-PDM supplied its Omicron optical fiber connectors to BBC Studios for use in its upcoming underwater natural history series, set to air in 2026. Filming required custom-built camera technology designed to capture extraordinary marine footage from the depths of the Arctic, facilitated by the Rev Ocean’s Aurora ROV.To capture groundbreaking underwater content BBC Studios and Marine Imagine Technologies designed a deep ocean-rated camera system integrated with a telemetry bottle, the central hub for communications on the submersible. However, during the Arctic expedition

MacArtney's GreenLink Tech Picked for First Grid-Linked Wave Energy Test Site in US

and test them.MacArtney’s technicians will help install and test the GreenLink terminations onsite with cable supplier Nexans.RT Casey will be overseeing the installation and testing of the GreenLink terminations onto the subsea cable in Norway at the cable factory, transportation of cable and connectors to Oregon, and the safe subsea installation of GreenLink from their cable installation vessel to the sea floor for future system connectivity."We have a proven concept and a proven connector for harsh marine conditions already operative in global projects. Our end-to-end approach - from concept

BIRNS High Amperage Connector Series Debuts

BIRNS made a big splash at Oceanology International in London last week at the company’s Power Forward event, with the celebration of the company’s 70th anniversary, and the launch of an all new high amperage subsea connector series, the 225 Amp BIRNS Meridian line.The Meridian line, a robust, custom engineered dry-mate connector series is open face rated to 6km, and is well-suited for battery packs and thrusters for crewed and uncrewed subsea vehicles that require high amperage power transfer. Select sizes are already being DNV type-approved for 6km rated crewed submersibles.

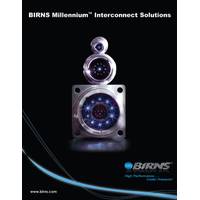

Birns Offers New Millennium Interconnect Catalog

Birns, Inc., introduced the new BIRNS Millennium Interconnect Catalog, a catalog that includes a significant expansion of pin configurations, direct links to downloadable configuration drawings, and comprehensive, strategic additions to product selection and part numbering guides, as well as highly detailed specification tools to walk the user through the selection process.The catalogue features a new, highly detailed RF section, which highlights BIRNS’ recent breakthroughs with low losses and better VSWR, for example: -.32dB loss and 1.17 VSWR at 1.5GHz. It also outlines the company’s

Blue Robotics Expands on the WetLink Line

WetLink family of products. The WetLink Penetrator (WLP) is Blue Robotics’ next-generation solution for low-cost, high pressure, high reliability sealing of electrical cables asthey pass into enclosures or other devices. It’s rated to a depth of 950m (3,116 feet) and compared to subsea connectors or penetrators, the WLP is a fraction of the cost while offering validated reliability. The WetLink Penetrator line now has cable gland sizes compatible with cables between 3.7mm to 9.8mm diameter.The patent-pending design of the WLP is based on a compression gland seal design, optimized for sealing

December 2025

December 2025