Ashtead Technology, Hydrollica to Provide Seawater Tooling Technology

the Hydro Multi-Tool, Hydro Micro Multi-Tool and Hydro PowerPack. These compact yet powerful tools are designed to deliver high performance across a wide range of subsea operations while replacing traditional hydraulic oil with seawater, significantly reducing environmental risk.Unlike traditional hydraulic systems, Hydrollica’s tooling operates using seawater, eliminating the need for hydraulic oil and reducing the risk of contamination. This innovation is particularly relevant as subsea operators across renewables, oil and gas, salvage and marine construction look for cleaner, more sustainable

Saab’s All-Electric Work Class Seaeye SR20 ROV Aces Water Trials

operational concepts such as resident deployment and over-the-horizon control.The all-electric vehicle, which uses limited oil, therefore reducing its environmental footprint, sets itself apart with its exceptional thrust and performance, electric manipulators, and impressive efficiency compared to hydraulic systems, Saab claims.Ocean Infinity is the SR20’s launch customer, transforming operations using innovative technology as they develop a fleet of uncrewed robotic vessels

Subsea Digitalization: Remote Control

, for example,” says Macleod.This is especially important for tiebacks into busy facilities, where plug-and-play power and communications result in much simpler topside modifications, much lower cost and much smaller environmental footprint rebuilding topsides.The elimination of high-pressure hydraulic systems is expected to enable operators to go further and deeper, improving production and making even marginal fields more viable.“Electrification is in some cases the only solution to achieve technical, commercial and operationally viable solutions for long distance developments. Using traditional

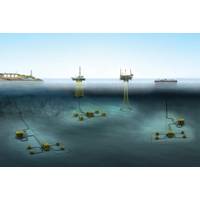

New Project Marks Tipping Point for Subsea Electrification

, for example,” says Macleod.This is especially important for tiebacks into busy facilities, where plug-and-play power and communications result in much simpler topside modifications, much lower cost and much smaller environmental footprint rebuilding topsides.The elimination of high-pressure hydraulic systems is expected to enable operators to go further and deeper, improving production and making even marginal fields more viable.“Electrification is in some cases the only solution to achieve technical, commercial and operationally viable solutions for long distance developments. Using traditional

SLB OneSubsea to Design All-Electric Subsea System for Equinor’s Fram Sør Field

made this milestone possible,” said Mads Hjelmeland, chief executive officer of SLB OneSubsea.The Fram Sør solution will use SLB OneSubsea’s standard subsea tree design, upgraded with a fully electrified power, control and actuation system, while the elimination of high-pressure hydraulic systems will enable operators to go further and deeper, improving production and making even marginal fields more viable.SLB OneSubsea is a joint venture backed by SLB, Aker Solutions, and Subsea7 headquartered in Oslo and Houston, with 10,000 employees across the world

LOTOS Petrobaltic Selects Saab Seaeye Leopard ROV for Subsea Work in Polish Oil Fields

custom-configured control cabin, along with additional peripheral systems."The 3000m-rated Seaeye Leopard is the top-selling electric work vehicle of its class and the most powerful of its size in the world, enabling it to tackle large and complex work tasks previously performed by much larger hydraulic systems. At half the size of an equivalent hydraulic work vehicle, operators find the Leopard more agile and responsive and able to handle stronger currents and wave motion. It can also tolerate higher environmental temperature ranges and has a considerable acoustic advantage for survey work over hydraulic

FET to Deliver Four ROVs to DOF Subsea

to deliver four of its advanced work-class remotely operated vehicles (ROVs).The ROV order comprises of two 200HP XLX-C’s, which have recently been delivered and mobilized in late 2022, as well as two 200HP XLX Evo II’s to be delivered in Q2, 2023, FET said. The XLX Evo II’s hydraulic systems have been redesigned in line with this contract and now share a vastly increased quantity of common component parts with the XLX-C’s, providing a customer benefit for spares commonality and subsequent availability, the manufacturer added.All vehicles are being manufactured at FET&rsquo

ABT-TRAC, WESMAR and SmartCatch Form INOV8V Marine

worlds first video sounder, first continuous picture color sonar, and introduction of the first dual-propeller counter rotational bow thruster.ABT-TRAC began as Arcturus Marine Systems in 1986. Best known in the yachting industry, ABT-TRAC specializes in stabilizers, bow and stern thrusters, and hydraulic systems. Its innovations include electrically driven stabilizers that deliver hydraulic performance without hydraulic overhead.SmartCatch began in 2012 with the mission of using innovative “eyes in the net” underwater video technology to maximize commercial fishing profitability while reducing

MacArtney to Supply All-electric LARS for SMD ROV

EV work class ROV (WROV) technology, specifically for the Atom-EV.MacArtney noted its eLARS offers several environmental benefits, including reduced risk of oil spillage with zero pressurized oil over water. The system provides approximately 30% better energy efficiency than traditional hydraulic systems, and maintenance is reduced by up to 50%, with the eLARS being fully electric, the company said.Related: Rovco Invests in SMD's EV Work Class ROVRelated: MacArtney Puts First All-electric LARS into Productio

February 2025

February 2025