Bardex Corporation, Gabriel Engineering Partner Up for Floating Wind Moorings

offshore wind.The partnership will investigate development of a U.K. production facility for anchor, mooring, and 'jewellery' (precision component) systems, critical to the stability and efficiency of GW-scale floating offshore wind farms.Bardex, headquartered in Goleta, California, with manufacturing facilities in Busan, South Korea, opened its U.K. subsidiary, Bardex Energy UK, in Newcastle in January 2025. With this new office and the partnership with Gabriel Engineering Group, Bardex aims to expand manufacturing capacity for its hydraulic chain jacks, mooring connectors, and tensioning

Technology Time - Newfoundland & Labrador Style

operations, as well as increased collaboration within NL and beyond.Nditive3D specializes in real-time gas detection and predictive analysis using an AI-powered monitoring system and patent-pending sensor technology. Ideal for high-risk industrial environments, Nditive3D serves chemical plants, manufacturing facilities, offshore energy, the mining industry and marine transportation.Kraken KATFISH towed synthetic aperture sonar system and autonomous launch and recovery system.© Kraken RoboticsKraken Robotics provides complex subsea sensors, batteries and robotic systems, with a focus on seabed

Prysmian Awarded $96 Million in Trade Secrets Dispute Against Sterlite

Italian cable maker Prysmian on Monday received about $96 million in its trade secrets case against India's Sterile Technologies.Prysmian filed the lawsuit in 2021 claiming that a former executive Stephen Szymanski misused trade secrets and took them to his new employer Sterlite, a networking technology provider.The trial found out that Sterlite possessed information regarding clients, products, and Prysmian's manufacturing facilities expansion.(Reuters - Reporting by Disha Mishra in Bengaluru)

Bekaert Joins Tailwind Floating Wind Moorings Innovation Project

effectiveness and sustainability of floating offshore wind farms, driving tangible cost savings while reducing dependency on primary raw materials.As a steel wire transformation and coating technology company, Bekaert also develops beyond-steel solutions with its Scottish-based synthetic rope manufacturing facilities, and due to its experience in offshore mooring systems, it was invited to join the Tailwind consortium.“I am very pleased that Bekaert is involved in the Tailwind project that will further enable the growth of floating offshore wind which plays an important role in accelerating the

Prysmian, Hitachi, BAM Get Cable and Converter Stations Contracts for UK Subsea Link

cable from Peterhead in Scotland to Drax in England.The longest HVDC cable in the UK and the UK’s single largest electricity transmission project ever, providing enough electricity to power 2 million UK homes.Prysmian has confirmed it has the capability to deliver the project with its manufacturing facilities for the production of the HVDC cable and its cable laying vessels for the installation in the timescale required for EGL2 to meet its targeted energization date in 2029, supporting the timely delivery of this project and mitigating risks associated with global constraints in the HVDC supply

Balmoral Group Boss Jim Milne Receives Knighthood

; buying, renovating and selling cars while at school before acquiring an 84 x 21ft ex-RAF hut from Kinloss to start up my first glassfibre manufacturing operation on the family Home Farm of Tullos.”Nowadays, Balmoral Group operates from a 45-acre site in Aberdeen and has engineering and manufacturing facilities in Newcastle, South Yorkshire and South Wales, all run by dedicated and committed individuals which he feels is so important."I’m a great believer in people. If you have good people, look after them; I can certainly say we have an abundance of good people at Balmoral that have

Geotechnical, Marine, and Coastal Design Solutions for Marshaling Ports to meet US Offshore Wind Power Policy Targets

GW of offshore wind power by 2030, increasing the Bureau of Ocean Energy Management’s (BOEM’s) leasing awards, and permitting target approval dates, together with more state energy procurement awards, are creating demand for more port infrastructure, Jones Act compliant vessels, and manufacturing facilities for wind farm components. Recently a study (Parkison, Sara B. and Willett Kempton, "Marshalling Ports Required to Meet US Offshore Wind Power Policy Targets" Energy Policy, Volume 163, April 2022), concluded that supply (and storage area) of US marshalling port infrastructure

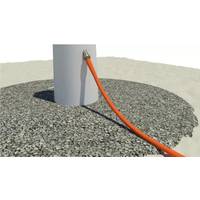

Trelleborg's Cable Protection for Chinese Offshore Wind Farm

, located in Jiangsu, China. Trelleborg’s NjordGuard cable protection system will protect inter-array grid power cables on the project from over-bending, abrasion, and fatigue. Production of the 190 NjordGuard cable protection systems will take place across Trelleborg’s manufacturing facilities in Singapore and England. Project engineering works will commence immediately, with installation activities scheduled for execution at the beginning of 2021.NjordGuard is an integrated cable protection system designed and developed to protect offshore wind farm power cables in wind turbine

The Emerging U.S. Offshore Wind Industry in a Post-COVID-19 World

American Wind Energy Association predicts that the offshore wind projects could create up to 83,000 jobs and $25 billion in annual economic output by 2030. Already, the AWEA reports, companies have announced well over a billion dollars in port-related infrastructure, transmission infrastructure, manufacturing facilities and supply chain development.Meanwhile, in other parts of the world, offshore wind development and infrastructure is already well developed, particularly in places like northern Europe where the first offshore wind farm was erected in 1991. Unsurprisingly, many companies from those markets

August 2025

August 2025