KIMM, Natural Resources Canada Sign MoU on Clean Technology Cooperation

automation, composite-based aircraft production, and maintenance technologies. During the visit, they met with Ibrahim Yimer, Vice President of the Transportation and Manufacturing Division at NRC, along with affiliated researchers, to explore potential collaboration in the field of intelligent manufacturing processes. The institutions also explored organizing technical seminars and facilitating researcher exchanges to establish practical collaboration frameworks.KIMM also visited the Montreal Institute for Learning Algorithms, one of the world’s leading AI research institutes, to discuss joint

Novielli Boats Unveils Plans for New Production Facility

in boats that blend form, function, safety, and power has led the company to expand its manufacturing capabilities on a global scale.Throughout its history, Novielli has adhered to rigorous standards in building both the hull and the inflatable tube components. Each craft emerges from meticulous manufacturing processes that bolster longevity. Naval engineers and design teams collaborate closely on every project, analyzing stress factors, optimizing buoyancy, and ensuring excellent handling and comfort. As market share continues to rise, leadership at Novielli has made the strategic choice to reinforce

Teledyne Cable Solutions Receives 'Blue Thumb' Award

a ceremony on November 14.“Everyone here are early adopters, you chose to keep your water clean even before there were regulations mandating compliance,” said a representative of City of Dallas at the ceremony.Teledyne Cable Solutions uses contact and non-contact cooling water in its manufacturing processes. TCS has permit from City of Dallas to discharge industrial wastewater into the sanitary sewer. TCS has received the award for staying within categorical discharge limitations. To ensure compliance with City regulations, TCS takes educational steps with all employees that interact with the

DEEP's #OccupyMare is about Persistent Human Presence Subsea

of US Office of Naval Research Undersea Medicine Program's Predoctoral Award. Dr Kernagis' team currently conducts advanced research for a number of organizations, including the United States Department of Defense and NASA. Following two years of research into advanced manufacturing processes and materials science, including the design of the largest WAAM 3D manufacturing capability in Europe, DEEP has received design approval in principle from DNV. "The Sentinel system is not theoretical, nor is it just renderings marketed to help raise capital or generate interest - we

Austal USA Awarded US Navy TAGOS-25 Contract

‘small waterplane area twin hull’ (SWATH) vessels support the Navy’s Integrated Undersea Surveillance System (IUSS) by gathering underwater acoustical data using Surveillance Towed-Array Sensor System (SURTASS) equipment.Austal said it will construct TAGOS using its proven ship manufacturing processes and innovative production methods that incorporate lean manufacturing principles, modular construction, and moving assembly lines in the company’s state-of-the-art enclosed steel production facility. Through continual capital investments, Austal USA has expanded its capability

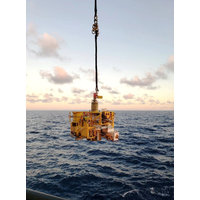

TechnipFMC to Deliver Subsea Production Systems for TotalEnergies' CLOV3 Project Offshore Angola

optimize subsea developments.According to TechnipFMC, Subsea 2.0 products use standardized components that are pre-engineered and qualified, which allows equipment to be rapidly configured according to each project’s specific requirements. This optimizes the engineering, supply chain, and manufacturing processes, thus reducing the time to first oil and/or gas. More Than 350 Subsea Trees to Be Ordered in 2022, Level Not Seen Since 2013, TechnipFMC Say

"CTO in Focus" - Gareth Davies, Baker Hughes

, the increase in the demanded speed for the delivery?It means we’ve changed how we think about designing and manufacturing our products. We have developed structured solutions that enable more repeatable manufacturing and less engineering on a repeatable basis. We have evolved our manufacturing processes to enable us to build a tree from order to exit, ex-works in 12 months. So that's something that was a great challenge in a positive way for us and forced us to think about how we can be as efficient as possible in that build process.You also mentioned in that interview, something about

Valeport Achieves 'Made In Britain' Status

and maintaining production here in the UK," said Matt Quartley, Valeport managing director. "We also believe it highlights the quality of our products and expertise gained from over 50 years of British manufacturing expertise.”Valeport retains all aspects of developing and manufacturing processes in-house, an approach which means they have total control over every stage of the manufacturing process and can guarantee the quality and consistency of their products. The company’s riverside premises house all the facilities for designing, CNC machining, environmental testing, assembly

TMS to Use 3D Printers for Submarines

now come to the Kiel Fjord. It is planned to complete the transition by June 2020.Dr. Luis Alejandro Orellano, COO of thyssenkrupp Marine Systems said: "3D printing opens up completely new potentials for us. In the design engineering, we no longer have to consider the limits of conventional manufacturing processes everywhere. In this way, we give our customers more freedom in the design of the boats."Orellano added: "At the same time, we can produce components faster and more cost-effectively. Bringing the necessary expertise and equipment to serve us in Kiel is the prerequisite for being

December 2025

December 2025