GeoAcoustics Expands Sonar Cable Molding and Assembly Services

Hydroacoustic technology manufacturer GeoAcoustics Ltd announced an expansion of its custom cable moulding and assembly services for subsea equipment manufacturers, marine systems integrators, and offshore contractors at Ocean Business 2025.The expansion follows GeoAcoustics’ acquisition of a specialist cable moulding company located near its Great Yarmouth headquarters. This move unlocks increased capacity and specialist expertise, enabling the delivery of complex, high-reliability cable moldings and terminations for a wide range of marine and subsea applications.Cable molding is a critical

Ocean Business '25: GeoAcoustics Ltd.

GeoAcoustics aims to launch new sonar products and expanded services for subsea equipment owners and OEM customers at Ocean Business 2025 in Southampton, UK, April 8-10.Visitors to the hydroacoustic technology manufacturer’s stand, H4, can find out about the company’s first new side scan sonar systems in more than ten years. With a choice of two dual frequency models, the new sonar promises cost-effective high-resolution data for a wide range of diverse applications.“Last year’s launch of GeoPulse 2 expanded our sub-bottom profiler range and we are keen to introduce more new

Teledyne Marine autonomously surveys DEEP's quarry lake in Wye Valley

a Teledyne RESON SeaBat T51 (800 kHz) multi beam sonar with integrated inertial navigation, paired with a Teledyne Valeport SWiFT profiler. Loch Lyr serves as the centerpiece of the DEEP campus, a facility spanning 50 acres. The former National Dive Center offers environment for testing subsea equipment, developing methodologies, and training personnel in controlled conditions. The lock stretches 500 meters in length, up to 125 meters in width, and plunges to 80 meters deep.The SeaBat T51's controls were tailored for autonomous operations to map the quarry, while the SWiFT profiler complemented

Koil Energy, SubseaDesign Join Forces for Subsea Field Development

solutions tailored to this segment. This alliance will allow us to reach a significantly larger market more quickly. SubseaDesign is an ideal partner, enabling us to engage more effectively with our European clients and offer them local capabilities,” added Erik Wiik, CEO of Koil Energy.US Subsea Equipment Firm Sets Up Shop in Brazi

US Subsea Equipment Firm Sets Up Shop in Brazil

Houston-based subsea equipment and services provider for oil and gas sector Koil Energy has established a new technology center for manufacturing and service support in Macaé, marking its expansion into Brazil.Macaé is generally considered to be the center of the offshore petroleum industry in Brazil, and it is often referred to as ‘Cidade do Petróleo’.Koil Energy has leased a 180,000 sq ft property with offices and a workshop of 27,000 sq ft. The facility will house engineering, manufacturing, testing and service support activities.The subsidiary, KOIL Energy Solutions

Kystdesign Books Its Largest ROV and Subsea Equipment Order to Date

a rapid timeline, which is a challenge we have accepted. We look forward to a long and mutually rewarding relationship with this new client.“This partnership marks the beginning of a promising collaboration, opening opportunities for future projects and strengthening our presence in the worldwide subsea industry. This contract positions Kystdesign for significant growth and increased marked shares in the coming years,” said Olafur Gislason, Sales and Business Development Manager at Kystdesign

Tritech Launches New Gemini Sonar

kits (SDKs) are also available for Windows and Linux operating systems“With its ultra-low-noise differential analogue front-end supporting a wide dynamic range optimised for sonar imaging applications, and with its ability to actively attenuate waterborne electrical noise from other subsea equipment, the Gemini 1200id provides work class ROV operators the clarity and confidence necessary for mission critical operations,” added Asim Azad, Hardware Engineering Manager

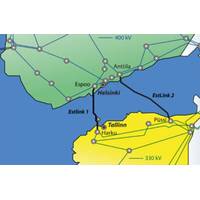

Estonia Launches Navy to Protect Baltic Sea Power Link After Baltic Sea Outages

power cable which, like Estlink 1, connects Finland and Estonia, and that it also damaged four internet lines.Baltic Sea nations are on high alert for acts of sabotage following a string of outages of power cables, telecom links and gas pipelines since Russia invaded Ukraine in 2022, although subsea equipment is also subject to technical malfunction and accidents.Damage to subsea installations in the region has now become so frequent that it is difficult to believe this was caused merely by accident or poor seamanship, Tsahkna said on Thursday.Finnish investigators believe the seized ship - the Cook

Police Looks Into Foreign Ship’s Role in Estonia-Finland Interconnector Outage

ship was involved in the damage of an undersea power cable connecting Finland and Estonia following a sudden outage on Wednesday.Baltic Sea nations are on high alert for potential acts of sabotage following a string of outages of power cables, telecom links and gas pipelines since 2022, although subsea equipment is also subject to technical malfunction and accidents.The 658 megawatt (MW) Estlink 2 power interconnector remains offline following the outage that began at midday local time on Wednesday, leaving only the 358 MW Estlink 1 in operation between the two countries, operator Fingrid said."

February 2025

February 2025