Improving Monopile Installations with Fugro’s InclinoCam

The offshore wind market is developing rapidly. More wind farms and larger wind turbines are being built, increasing the requirements for verticality, and therefore the need for accurate, efficient and safe verticality monitoring. This in turn has led to the development of Fugro’s newly launched InclinoCam, which is featured on Fugro’s stand (30A100) at EWEA Offshore 2013.

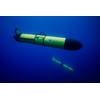

“The need to measure verticality of wind turbines starts with the foundation,” explained Dieuwertje Smallenburg, Positioning & Remote Services Manager at Fugro Survey BV. “Most offshore wind turbines are founded on monopiles that typically measure 70 meters in length with a diameter of 6.5 meters weighing 850 metric tons. These monopiles are driven into the seafloor using a hydraulic hammer, a process which can take several hours, so verticality is a key requirement. Previously inclinations of 1º were tolerated, but with the increasing size and developing technology 0.25º is now generally used as maximum tolerated inclination.”

Traditionally the verticality - or inclination - is measured by hand-held inclinometers. Due to irregularity of the outside pile surface, the manual inclination measurements do not always result in an accurate representation of the inclination of the entire pile and will require more measurements to reach the required accuracy. This causes delays in the piling operations as the hammering has to stop for the measurement and processing of the information for the crane and hammer operators. Furthermore the manual inclination monitoring has clear HSE disadvantages.

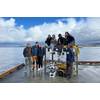

Fugro’s InclinoCam, an innovative inclination monitoring system eliminates these disadvantages and has already proven its value in practice. The system enables continuous real-time verticality monitoring without delays and without the need for people on the deck. The system is based on intelligent visual object recognition combined with vessel motion compensation.

Two high-resolution cameras are placed at an angle pointing towards the monopile, thus measuring the inclination in two directions. To compensate for vessel movement the cameras are connected to Inertial Motion Units (IMUs). The camera images and IMU data are synchronized using Fugro’s StarPort technology.

All information is received in Fugro’s comprehensive Starfix.NG navigation suite and the results are visualised on screen with a simple and intuitive user interface. With InclinoCam the hammer operator has access to crucial continuous real-time information on the inclination allowing for immediate correction of deviations in verticality. This is essential especially during the first phase of hammering in order to keep within the required verticality tolerance.

“New operators who start using the InclinoCam as a secondary system, soon change it to their primary system, once they experience its high level of reliability, user-friendliness, and time-saving ability on monopile installations, where it improves both verticality and safety,” concluded Dieuwertje Smallenburg.

February 2025

February 2025