Proserv Expands Subsea Test and Assembly Facility

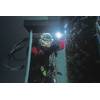

International energy technology services company Proserv has grown its subsea test and assembly center in Aberdeenshire after investing in additional skilled personnel, new equipment and facilities.

New features at the cutting-edge facility, which has doubled its capacity in the last 18 months, include two purpose-built surface test bays; a purpose-built cell for tubular and riser testing; 200-ton SIT areas, fully serviced for stack-up testing; upgrades to the existing test pit facilities with all controls at surface; new, fully-serviced client SIT offices complete with conference, Internet and office facilities; a purpose-built clean room within the workshop for sampling and testing of control fluids and a LEAN (lean manufacturing, lean enterprise) team.

Additional features added to further enhance the efficiency and cost effectiveness of Proserv’s operations are quality driven flow processes, additional communication tools and tool bay upgrades to minimize downtime.

Members of the Proserv team showcased the enhanced facilities at Birchmoss, Echt on Friday (June 7) where the company has also brought its range of subsea capabilities – subsea services, controls, and inspection and calibration services under one integrated organization.

Proserv’s facility is believed to be the only one of its kind in the U.K. in terms of its size and industry-leading capabilities, the company said. Complete with large test pits and 75-ton internal craneage, the facilities are used for the design testing, maintenance and installation of subsea equipment including tree assembly, system integration tests, factory acceptance tests, and blow-out preventer recertifications prior to deployment offshore or subsea.

Mark Williams, who was recently appointed as Proserv general manager with responsibility of overseeing the Birchmoss operation, said, “Building upon our facilities at Birchmoss and creating even leaner processes further reinforces Proserv’s track record for delivering integrated solutions in market-leading response times. This, in turn, significantly increases the added value we provide for our clients.”

“Our robust processes are further underpinned by the recent introduction of the internationally-recognized Lean Six Sigma and 5S quality management systems and environment which ensures the training and development of staff at every level.”

Proserv, which runs a Technician Apprentice Program accredited by SQA (Scottish Qualifications Authority), this program, attracts fresh blood into the talent pool and provides an excellent start to a Technician’s career in Proserv.

Mr. Williams said, “We have developed a bespoke training program from which we can tailor a personal development plan for each individual according to their skills and training needs. This includes a mentoring and coaching program which is proving very successful. The oil and gas industry is an exciting industry to work in and Proserv offers long-term career opportunities on a global platform.”

He added, “Proserv is actively working to attract new talent into the industry and as part of this drive, the company is holding a recruitment event at Aberdeen’s Maritime Museum on June 27 to give people a greater insight into the career opportunities within the organization.”

www.proserv.com

December 2025

December 2025