Seahorse Armor Gives Insight Into Robotics Designs

The tail of a seahorse can be compressed to about half its size before permanent damage occurs, engineers at the University of California have found. The tail’s exceptional flexibility is due to its structure, made up of bony, armored plates, which slide past each other. Researchers are hoping to use a similar structure to create a flexible robotic arm equipped with muscles made out of polymer, which could be used in medical devices, underwater exploration and unmanned bomb detection and detonation. Researchers, led by UC San Diego materials science professors Joanna McKittrick and Marc Meyers, detailed their findings in the March 2013 issue of the journal Acta Biomaterialia.

“The study of natural materials can lead to the creation of new and unique materials and structures inspired by nature that are stronger, tougher, lighter and more flexible,” said McKittrick, a professor of materials science at the Jacobs School of Engineering at UC San Diego.

McKittrick and Meyers had sought bioinsipiration by examining the armor of many other animals, including armadillo, alligators and the scales of various fish. This time, they were specifically looking for an animal that was flexible enough to develop a design for a robotic arm.

“The tail is the seahorse’s lifeline,” because it allows the animal to anchor itself to corals or seaweed and hide from predators, said Michael Porter, a Ph.D. student in materials science at the Jacobs School of Engineering. “But no one has looked at the seahorse’s tail and bones as a source of armor.”

Most of the seahorse’s predators, including sea turtles, crabs and birds, capture the animals by crushing them. Engineers wanted to see if the plates in the tail act as an armor. Researchers took segments from seahorses’ tails and compressed them from different angles. They found that the tail could be compressed by nearly 50 percent of its original width before permanent damage occurred. That’s because the connective tissue between the tail’s bony plates and the tail muscles bore most of the load from the displacement. Even when the tail was compressed by as much as 60 percent, the seahorse’s spinal column was protected from permanent damage.

McKittrick and Meyers’ research group uses a unique technique that applies a series of chemicals to materials to strip them of either their protein components or their mineral components. That allows them to better study materials’ structures and properties. After treating the bony plates in the seahorse’s tail with the chemicals, they discovered that the percentage of minerals in the plates was relatively low—40 percent, compared to 65 percent in cow bone. The plates also contained 27 percent organic compounds—mostly proteins—and 33 percent water. The hardness of the plates varied. The ridges were hardest, likely for impact protection—about 40 percent harder than the plate’s grooves, which are porous and absorb energy from impacts.

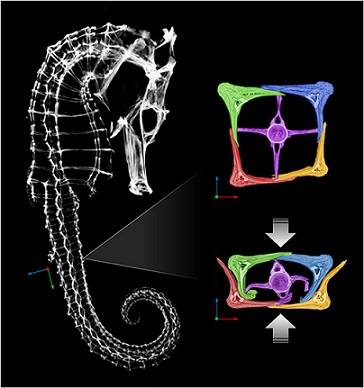

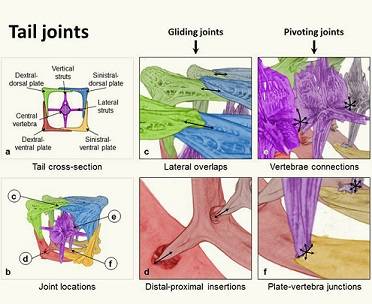

The seahorse’s tail is typically made up of 36 square-like segments, each composed of four L-shaped corner plates that progressively decrease in size along the length of the tail. Plates are free to glide or pivot. Gliding joints allow the bony plates to glide past one another. Pivoting joints are similar to a ball-and-socket joint, with three degrees of rotational freedom. The plates are connected to the vertebrae by thick collagen layers of connective tissue. The joints between plates and vertebrae are extremely flexible with nearly six degrees of freedom (See picture).

“Everything in biology comes down to structures,” Porter said.

The next step is to use 3D printing to create artificial bony plates, which would then be equipped with polymers that would act as muscles. The final goal is to build a robotic arm that would be a unique hybrid between hard and soft robotic devices. A flexible, yet robust robotic gripper could be used for medical devices, underwater exploration and unmanned bomb detection and detonation. The protected, flexible arm would be able to grasp a variety of objects of different shapes and sizes.

February 2024

February 2024