AI Goes Subsea: Autonomous Welding Robot Debut

Underwater welding is one of the most demanding and hazardous tasks in the maritime and offshore world, relying heavily on a small, highly specialized pool of industrial divers. As port infrastructure ages and offshore structures expand, demand for underwater repair continues to outpace available manpower. A new research project out of Germany aims to fundamentally change that equation.

Led by the German Research Center for Artificial Intelligence, the MARIOW (Maritime AI-Guided & Remote Operated Welding) project has developed a robotic system capable of performing underwater welding tasks largely autonomously. The technology combines artificial intelligence, advanced sensing and a purpose-built underwater robotic arm, laying the groundwork for automated subsea repairs that reduce risk, improve consistency and scale far beyond today’s diver-centric approaches.

Funded by Germany’s Federal Ministry for Economic Affairs and Energy (BMWE), MARIOW brings together a consortium spanning robotics, materials science, computer vision and industrial welding expertise. Partners include the DFKI Robotics Innovation Center in Bremen, the TH Köln, the Fraunhofer Institute for Computer Graphics Research IGD, AMT GmbH and Unterwasserkrause – Mutzeck GmbH.

A Modular Manipulator Built for the Deep

At the heart of the MARIOW system is a modular underwater manipulator developed by DFKI. Designed for operation at depths of up to 6,000 meters, the robotic arm offers a two-meter reach and can be adapted to a range of welding scenarios on ports, offshore platforms and other submerged steel structures.

Precision is achieved through a hybrid control approach that combines decentralized joint control with higher-level motion planning. The result is repeatable, stable execution of welding tasks—an essential requirement when working in low visibility and high-current underwater environments.

Letting AI Find the Weld

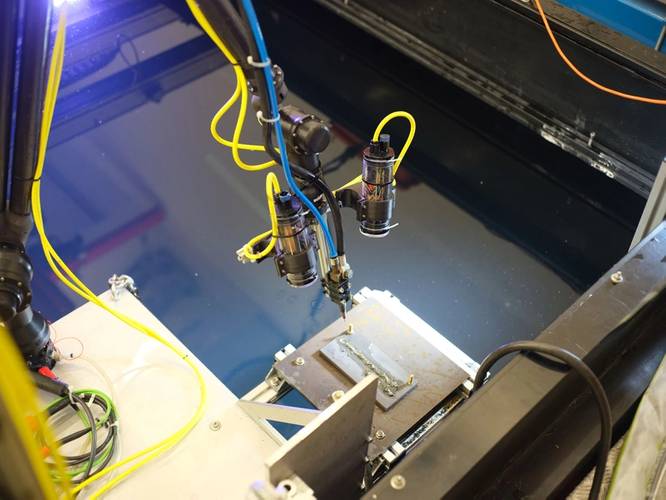

One of MARIOW’s most significant advances lies in how the system determines where—and how—to weld. A stereo camera system developed by Fraunhofer IGD provides high-resolution imagery directly at the welding torch. Using this visual data, AI models developed by the Laboratory for Autonomous Systems at TH Köln autonomously identify weld joints, as well as their start and end points.

Once the joint geometry is recognized, the AI calculates the optimal welding path, adjusting robot motion accordingly. This capability enables consistent weld quality even when visibility is poor—conditions that routinely challenge human divers.

Continuous Wire Unlocks Automation

Automation would not be possible without a fundamental shift in the welding process itself. Traditional underwater welding relies on stick electrodes that must be replaced after only a few centimeters of weld, making continuous robotic operation impractical.

To overcome this limitation, the consortium developed an underwater flux-cored arc welding (UW-FCAW) process. Created by the Institute for Materials and Process Technology at TH Köln in collaboration with AMT GmbH, the system replaces stick electrodes with a continuous wire feed. This uninterrupted material flow enables stable, controlled and reproducible weld seams—an essential prerequisite for autonomous operation.

From Lab to Harbor Basin

The fully integrated MARIOW system was demonstrated in DFKI’s underwater test basin in Bremen, where the consortium successfully showcased AI-based joint detection, automated path planning and robotic welding using the UW-FCAW process.

According to Christian Koch, project manager at the DFKI Robotics Innovation Center, the demonstration confirms that automated underwater flux-cored arc welding is not only feasible, but commercially promising for the maritime sector.

Next steps will focus on transitioning the technology from controlled environments to real-world harbor conditions. Salt water, waves and currents introduce new variables, while increased pressure at depth places higher demands on component sealing and durability. Future development will also integrate a laser system to remove welding slag, further improving seam quality and operational reliability.

If successful, MARIOW could mark a turning point for subsea maintenance — shifting underwater welding from a diver-limited craft to a scalable, AI-driven industrial process. Welding torch and stereo cameras on the robot end effector during test preparations in the Maritime Exploration Hall at DFKI Bremen

Welding torch and stereo cameras on the robot end effector during test preparations in the Maritime Exploration Hall at DFKI Bremen

Copyright: DFKI, Christian Koch

February 2026

February 2026