'Vibro-Installed' Anchor Concept gets support from U. of Dundee

The €3.7m UMACK Project will also now benefit from the University’s experimental and physical testingfacilities, developed as part of the Scottish Marine and Renewable Test Centre(SMART). Photo courtesy UMACK

A marine mooring and anchoring project aiming to improve the operation efficiency of ocean energy devices is recruiting support from the University of Dundee.

The UMACK (Universal Mooring, Anchor & Connectivity Kit) Project has teamed up with the University’s Geotechnical Engineering Group to aid the development of a new ‘vibro-installed’ anchor system for Marine Energy applications.

The new anchor solution developed in the UMACK project will form part of a high-capacity mooring system supporting wave energy developer, CorPower Ocean, with their first commercial scale demonstration project, HiWave-5, launching in Portugal later this year.

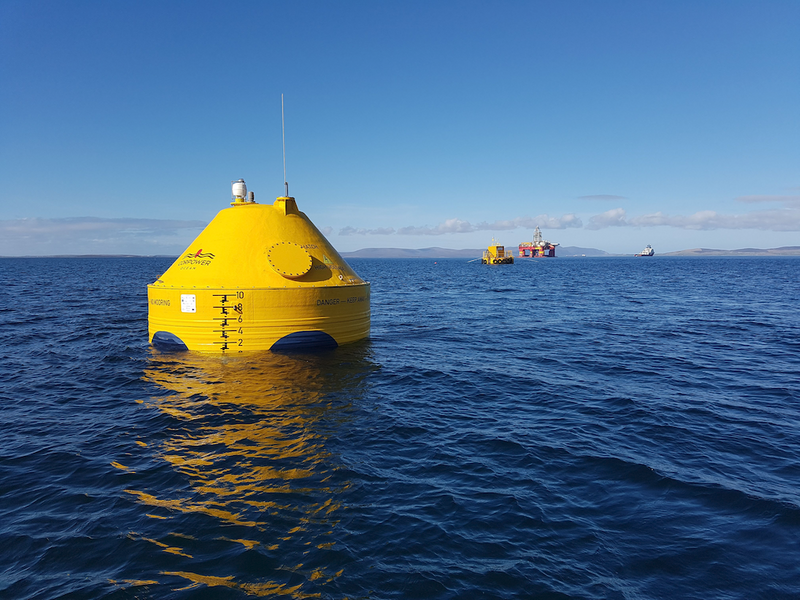

CorPower Ocean wave energy conversion buoy. Photo courtesy CorPower

CorPower Ocean wave energy conversion buoy. Photo courtesy CorPower

The €3.7m UMACK Project will also now benefit from the University’s world-leading experimental and physical testing facilities, developed as part of the Scottish Marine and Renewable Test Centre (SMART).

UMACK Project Manager and CorPower Ocean Head of Projects Matt Dickson said that the partnership marked a ‘significant breakthrough’ adding greater resource and expertise in the field of geotechnical engineering and science to the UMACK project team.

UMACK presents a step change in technology for the ocean energy space addressing issues around affordability, durability and reliability of marine power system’s mooring and anchoring. The UMACK solution is being developed to supersede widely used ‘gravity-based’ anchors – reducing CAPEX, installation and O&M (Operational & Maintenance) costs by more than 50%.

The consortium’s work with the University of Dundee is focusing on a novel ‘vibro-installed’ anchor system and involves world-class scaled anchor centrifuge testing and advanced computational modelling. The full-scale prototype anchor consists of a 1.5m diameter plain pile like structure with the novel UMACK pile tip end piece attached at the end which is then gradually vibrated into the seabed.

The UMACK pile tip design reduces soil resistance, enabling the anchor to be driven to the desired project penetration depth. Once the vibration stops, the UMACK anchor solution mobilises a large wedge of earth to provide a very large tensile capacity. The solution replaces the need for gravity-based anchors and also alternative large diameter plain pile anchors which are driven straight into the ocean floor, a noisy process known to be detrimental to marine life. Large diameter plain piles are also expensive, often forming in the region of 30-40% of development costs of a new offshore generation site.

Modelling work is now underway at 1/50th scale to rigorously test the technology and understand optimum configuration for ease of installation, adaptability to different seabed types and maximum uplift capacity. 3D-printed metal anchors are also being subjected to thousands of cycles of wave loading to assess lifetime performance.

December 2025

December 2025